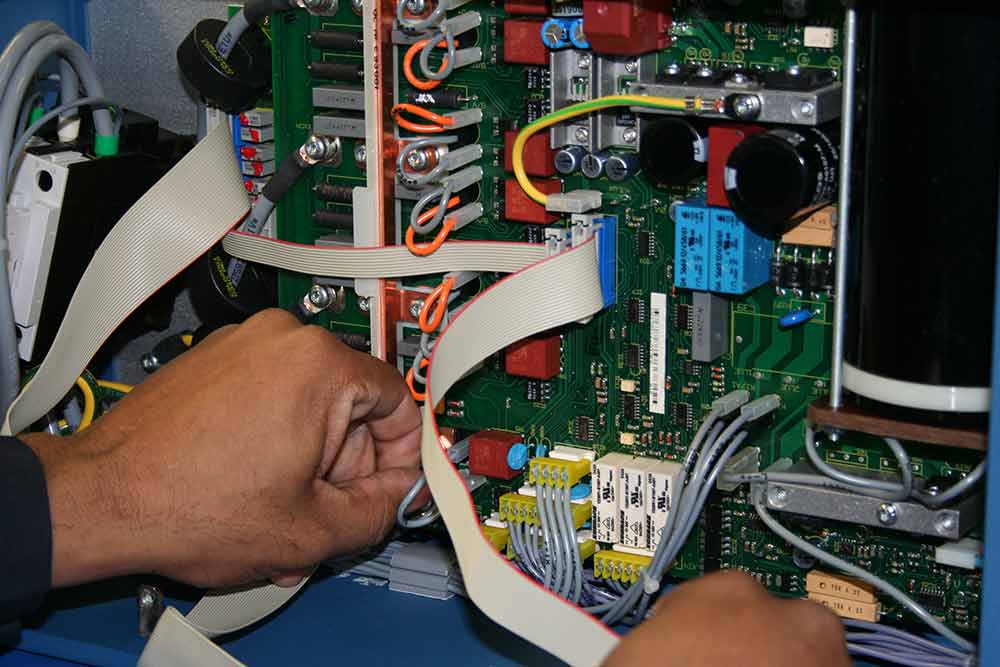

ETI Group has over 10+ years of experience repairing all types of AC / DC frequency & servo drives.

Our Engineering group has designed and built over 150 dedicated AC, DC and Servo Drive test stands to ensure each repaired unit is load tested to OEM specifications. Our custom-made dynamometer controls two motors working against each other for a dynamic load test that allows us to make performance and rating adjustments to exactly the right levels. Below are some of the Manufacturers we can help you with.

AC/DC frequency drives and servo drives with feedback are repaired and tested under load.

ETI Group can also support your needs through the sale of used, fully refurbished products. Whether your drive is no longer available new, you don’t have a broken unit to send out for repair, or you are just looking for ways to save money, contact us for a quote today! All of our refurbished sales come with a full 12 month warranty and are fully tested prior to shipment.

AC and DC Drive Repair You Can Depend On

Over time, repair of essential electronic components is a must to keep your business running smoothly. Even the best made and designed parts are subject to wear and tear, especially if your company commonly produces at a high volume. So, who can you trust when in search of AC and DC drive repair?

With a global presence and more than three decades of experience under their belts, ETI Group Services provides dependable service that has earned the respect of numerous manufacturers all over the world. What makes our company so different is our willingness to innovate. Not only do we offer AC DC motor repair, we also ensure your parts are operating at peak efficiency once repairs are complete. We do this by conducting multiple tests, which go above and beyond tests conducted by other electronics repair companies. These tests are integral for determining performance, and can also provide insight to the repair team when it comes to rating adjustments. Additionally, we’ve developed a specific process that starts with the receipt of your parts and ends with our experts taking all the proper precautions when shipping the item back to you. That way you can rest assured that your crucial components are in good hands every step of the way.

Evaluation of Your Equipment

Once your equipment is received, the first step in our ISO-Certified repair process is to evaluate it for all defects. While you most likely know how faulty parts are disrupting your work process, you may not be fully aware of the extent of the damage. Additionally, some components may be on the brink of failure, which means they will need to be repaired as soon as possible. That’s where our skilled and knowledgeable technicians come in. We’ll conduct a thorough review of the component to determine exactly why it’s failing. This information will help us devise a plan of attack for the necessary repair, as well as decide which tests should be run once repairs are complete. From here, we’ll provide a Failure Analysis Report along with a quote detailing the costs of repairs.

The Repair Process Begins

Once you’ve approved the quote, the repair process will begin. Components that have experienced total failure will be replaced. Additionally, components that are near failure will also be replaced to ensure lasting operation and prevent further issues down the line. We also utilize a tracking system that reduces the likelihood of errors or mistakes as the part progresses through the repair process. Closed-loop testing is a key part of the process in this case. Tests are designed to replicate performance within your facility to ensure repairs will hold up under similar amounts of stress. Tests will also be conducted for a specific length of time to provide the most accurate results possible.

Comprehensive Reports Are Issued

Along with quality service, technicians will also issue comprehensive reports on all the work performed. The first step is to go over the details of the evaluation process, which entails explaining what problems were found. Next, you’ll be privy to a complete listing of all parts that were replaced. This can help you track the age of these components to anticipate when service may be needed again. You’ll also receive a description of the testing process, along with the underlying cause of the initial failure. Lastly, you’ll receive detailed instructions on how the newly repaired component should be installed back into your machinery.

A Repair Process You Can Rely On, No Matter What

Whether you’re looking for help with AC and DC servo motors or require AC drive repair, ETI Group Services has the tools and the knowledge to get your equipment up and running again. Contact us today to learn more about the repair process, as well as access essential resources to expand your understanding of service. You can also request a quote today by using our convenient form.